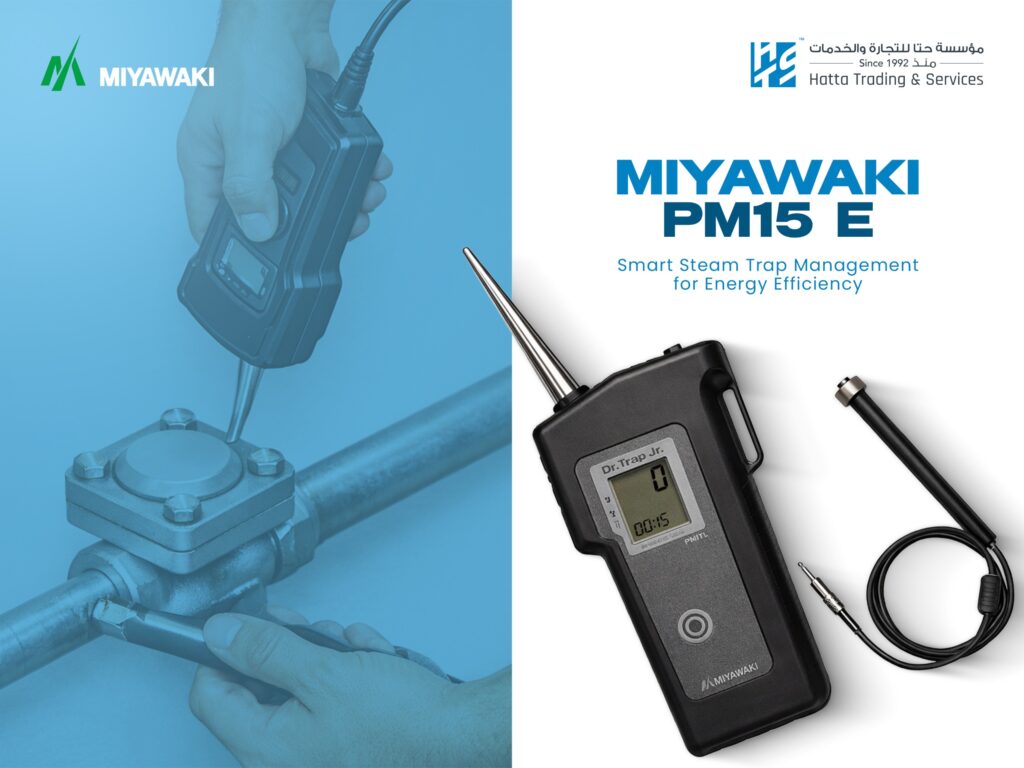

B-VAC™ Pro 4 Integrated Sponge-Blasting System

Sponge-Jet Integrated Systems combine three essential components of Sponge-Jet Technology:

Sponge-Jet Feed Unit™ for the delivery or blasting of Sponge Media™ products.

Sponge-Jet Recycler™ to clean and ready Sponge Media products for reuse.

Vacuum or material-handling system for recovery and transport of Sponge Media.

A range of systems both standard and custom are available for various applications.

Product Overview

The B-VAC™ Pro 4 integrates Sponge Jet’s Feed Unit™, closed top Recycler™, and highvolume vacuum ejector on a single, forklift ready frame. Delivering ≈ 2 hours of continuous blasting within a compact 246 cm × 155 cm footprint, it is designed for sites where space, time, and air quality are critical.

Key Features & Benefits

- Closed top, vacuum sealed Sponge Jet Recycler™

- High strength steel frame with integrated ladder, fork pockets & lifting eyes

- Blast pressure adjustment for multiple surface profiles

- High volume, low noise vacuum ejector (≤ 76 dB[A])

- Cyclone storage silos, moisture separator, and high-capacity muffler

- Centralised controls for precision monitoring and adjustment

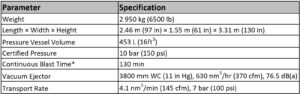

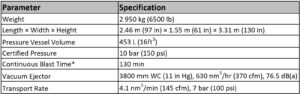

Technical Specifications

Typical Applications

- Oil & Gas platforms – fast spot repairs without hot-work permits

- Shipyards/Dry-docks – low-dust prep adjacent to other trades

- Bridge & Infrastructure – single-point lift tackles tight lane closures

- Power Stations – internal data shows 75 % faster turbine-deck turnaround

Return on Investment

While no published study isolates cost savings from the B-VAC™ Pro 4 itself

- Independent reviews of vacuum integrated sponge blasting on North Sea

platforms reported a ≈ 60 % reduction in indirect tasks such as masking and cleanup*

- And an industrial fabrication case study logged ≥ 50 % manpower savings with 80 % less unscheduled downtime.

- Your actual ROI will depend on crew rates, rental duration, and site constraints; use the table above to estimate productivity gains against local labour costs.

Why Choose B-VAC™ Pro 4?

Compact footprint, real-time recycling, and proven labour savings make B-VAC™ Pro 4 the go-to for high-value assets where every shift of downtime matters—backed by Sponge-Jet’s worldwide support and a 2-year equipment warranty.

For more details visit:

Visit site

User Manual

Kindly contact us for enquiries at: hatta@hatta.ae