Steam is one of the most valuable and costly utilities in industrial plants. The most efficient steam systems will lose their energy when steam traps are poorly maintained or fail. Research indicates that 20-30 percent of steam traps do not work when they are not checked frequently. The leakage of steam, water hammer, corrosion, and increased costs of energy can be detrimental to operations. Miyawaki Japan offers a solution to this problem with its PM15 E Steam Trap Management System – a powerful portable solution that is more reliable, safer, and more economical.

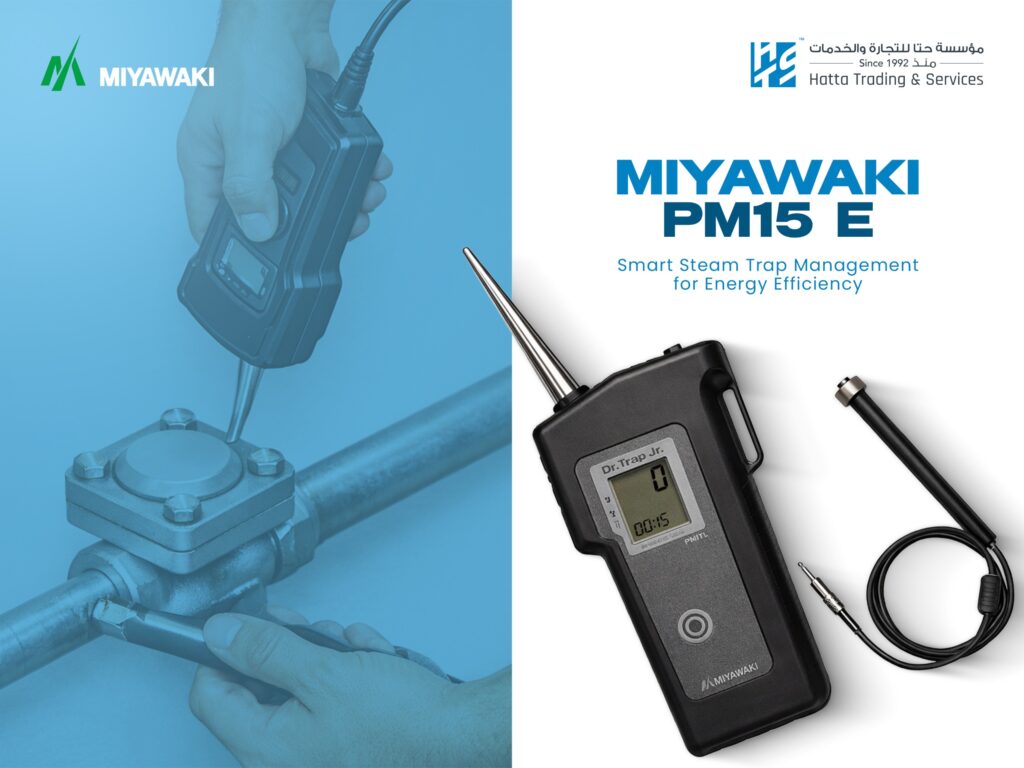

The Miyawaki PM15 E implements ultrasonic vibration sensors, temperature sensors, and intelligent software to be able to diagnose steam traps with precision. Manufactured in Japan, it is relied upon by engineers of maintenance and energy all over the planet to identify the presence of bad traps and waste steam.

Why Steam Trap Management Is Essential

The steam traps are used to remove the condensate but leave behind the live steam.

One of the traps that open wastes precious steam. A trap that remains closed allows condensate to accumulate and this may lead to water hammer and equipment damage.

A constant check by a professional steam-trap management system is necessary to assure correct operation of traps, safeguard the equipment, and minimize operation expenses.

Losses are avoided through good steam trap management resulting in:

- Lower energy consumption.

- Improved plant safety.

- Less corrosion and wear on the equipment.

- Increased piping and steam life.

Key Features of Miyawaki PM15 E

Accurate Steam Trap Diagnosis:

The PM15 E uses ultrasonic vibration readings to identify steam leakages, blockages and faulty traps. Also, it measures the surface temperature to confirm the condition of operating and enhance the diagnostic accuracy.

All-in-One Portable System:

The system includes:

- PM15 Ultrasonic Checker

- Temperature probe

- Lightweight, compact design for easy plant-wide surveys

Intelligent Analysis Software:

With SurveyPro Light software, users can:

- Analyze steam trap condition

- Classify failures (blow-through, blockage, cold trap, etc.)

- Store inspection data and track performance

Multi-Brand Compatibility:

PM15 E is compatible with all types and brands of steam-traps such as the thermodynamic, float, or even thermostatic steam-traps and is not restricted to the Miyawaki products.

How the PM15 E Works

- Tag & Register – Make a steam-tap database with location, type and manufacturer.

- On-Site Inspection – Measure ultrasonic vibration and temperature of the surface.

- Data Analysis – Upload data to SurveyPro Light to automatically diagnose.

- Reporting – Get clear reports that indicate which traps fail and what risk of loss of energy this indicates.

Typical Applications

- Oil refineries & petrochemical plants

- Power generation facilities

- Manufacturing and process industries

Partner with HATTA – Authorized Miyawaki Representative

HATTA is a certified agent of Miyawaki who provides full steam-tap management services:

- Supply of PM15 E systems

- Technical support

- Programs of improving energy efficiency.

Please find the below link for additional information

Read more

Kindly contact us for enquiries at: hatta@hatta.ae